How To Know When You Need To Replace Your HVAC Evaporator Coil

Evaporator coils are a hot topic when it comes to HVAC repairs in Northern Virginia. They’re an essential part of your HVAC system, and if your system isn’t running how it should be, you could be in trouble.

When left to its own devices, a bad HVAC evaporator coil could lead to you having to replace your entire HVAC unit, which isn’t exactly ideal.

So, today we’ll be talking about what an evaporator coil is, why it goes bad, and when you need to replace it to keep your HVAC unit running smoothly.

What is an HVAC evaporator coil?

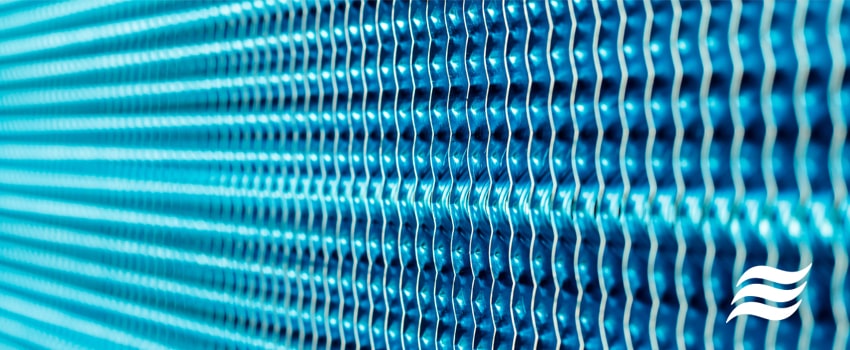

An evaporator coil, also called a coil or indoor coil, and it is one of the most important parts of your HVAC system. Essentially it’s what keeps the temperature in your home regulated throughout the year.

The evaporator coil is filled with refrigerant. As your HVAC system draws air from inside your home across the coil, the refrigerant evaporates it and absorbs the heat from the air.

During the summer months, the coil gives you cool air and serves as a dehumidifier, getting rid of any unnecessary moisture from the air.

Your evaporator coil has the most important job in your entire HVAC system. It keeps your home comfortable at all times.

How long does an evaporator coil last in Northern Virginia?

The coiled tubes of the evaporator coil are its primary surface. The coil's finned area performs 70% of the coil's work.

This is known as the secondary surface.

The bond between the finned area and the tubes is the most important feature in any coil. Without this bond, the coil can’t properly function. Over time the fin and tube bond becomes less and less efficient. The weak bond is due to the coil’s constant expansion and contraction as it does its job.

Even though the coil and fin’s construction doesn’t allow for movement, the fin and tube bond naturally weakens over time. Because of this, the coil can become about 30% less efficient over its 20-year lifespan.

Sometimes, homeowners try to clean the coil themselves, but this often pushes dirt to the center of the coil, causing more issues. That occurs more frequently when trying to clean wet cooling coils.

The BTU output of any coil is directly proportional to the amount of air going through the coil. Airflow is significantly decreased if dirt is pushed to the center of the coil.

For example, if you decrease the airflow by 20%, the BTU will also decrease by 20%.

Additionally, cleaning agents often corrode aluminum fins. Every square inch of the fin’s surface is important for performance. If the fin’s surface is corroded, the coil’s performance will suffer.

Old age is often the cause behind coil leaks as no coil is immune to erosion over time. Joints in the tubes and the header and tube connections also fail over time.

These joints have been melted together during manufacturing to form a cohesive unit. However, the steam can be both erosive and corrosive under higher pressures. Water travels through the coil at 2-5 feet every second, making erosion an enormous part of coil failure, regardless of how well-maintained it is.

Erosion is always there, whether you realize it or not. Water/steam treatment and the corrosive effects of bad steam/water can all be causes of coil failure over time.

What causes an evaporator coil to go bad?

There are many reasons why an evaporator coil goes bad, which is why getting it maintained is important. You can improve the longevity of your coil by getting it serviced regularly. With proper maintenance and care, your coil can last up to 20 years.

How to make an evaporator coil last longer

It’s important that you follow the precautions and recommendations given to you by your service technicians to help improve your coil’s lifespan.

Here are some things you should keep in mind to help avoid expensive repairs down the line:

1. Change your HVAC filter monthly

A lot of evaporator coil issues can be prevented by simply changing the filter in your HVAC unit every 30 days.

If the filter isn’t changed, dirt can be pulled into the system, affecting the coil and other parts of your HVAC unit.

The evaporator coil needs to breathe easily to allow the air from your home to move across it. It can’t breathe effectively if your filter is clogged with dirt. If it’s left too long, the coil will become clogged with dirt and will freeze, causing water to leak out.

Water leaks are due to the refrigerant building up too much discharge pressure because the volume of air needed to maintain the system’s pressure isn’t there. In turn, this stresses the joints on the condenser coil, which can lead to a line popping and a refrigerant leak that can cost you thousands in repairs.

Regularly changing the filter regularly can prevent these issues from happening.

2. Make sure the HVAC motor can breathe

The blower has slotted vents for the HVAC motor to breathe.

If the motor can’t breathe as needed, it’ll eventually go bad.

It’ll start by drawing high amps and eventually overheat until the silicone bindings inside completely fail.

Make sure these vents stay clear of any debris or dirt so your motor can easily breathe. It’ll save you a lot in future repairs.

3. Clean the condenser outside

The condenser outside gets a huge buildup of dirt, leaves, grass, debris from trees, and other outdoor debris. The condenser coil on the outside unit is just as important as the evaporator coil on the indoor unit. In fact, the evaporator coil often fails due to issues with the condenser coil.

As the condenser fan spins, it attempts to draw air across the condenser coil and through to the evaporator coil.

If you let the condenser coil get too dirty, it will build up pressure. This could cause the evaporator and compressor to fail, leading to expensive repairs.

Make sure your condenser outside is clean, and there isn’t any debris covering it.

How to avoid damaging your evaporator coil

Technicians will often recommend that you get your evaporator coil, your condenser coil, and your motor cleaned regularly.

You might think that they’re just trying to get you to spend more money on something you don’t need, but this isn’t the case at all.

As trained service technicians, we have seen systems fail left and right from lack of proper maintenance. An HVAC is a finely tuned machine, and like a vehicle, it needs to have parts fixed and replaced regularly.

When your technician makes a recommendation, don’t ignore it. Remember: a $200 cleaning fee now can save you from a $2,000 repair later.

When should you replace an evaporator coil in Northern Virginia?

If the coil is leaking, it needs to be replaced.

The cost of cleaning will only be more expensive than the cost of a replacement coil. Plus, cleaning your coils will only guarantee the coil’s efficiency back to 50-75%.

If you think your evaporator coil is getting on in years or it hasn't had any maintenance done in a while, we can help.

Our team of skilled HVAC technicians in Northern Virginia can help you fix or replace your evaporator coil to help prevent any future, expensive repair jobs.

If you need any help with your HVAC system or have any questions or concerns, please feel free to contact us today.

Check out our other blogs for some great HVAC advice:

- Monthly Guide To HVAC Maintenance

- The 5 Biggest HVAC Myths

- How to Get Your AC Read For Summer After A Long Winter

- Pet Owners! Get More Life Out Of Your HVAC Unit With These 6 Tips

- Gas Leaks and How to Prevent Them

- How to Remove Humidity From Your Home

- Signs of a Damaged Furnace Heater

- 5 Biggest HVAC Myths

- 5 Tips For Spring Cleaning Your HVAC System